Dr Peter Schemmel is a postdoctoral researcher in Applied Photonics at Heriot-Watt University. He is part of the team at the Institute of Photonics and Quantum Sciences in a group which focuses on stress analysis in ceramics and engineering plastics. They are particularly interested in ceramic thermal barrier coatings used on aeroplane engine turbine blades or power generating turbines. Typically, the air around these blades is hotter than the melting point of the blades themselves. Therefore, they must be coated with a ceramic thermal barrier coating. These coatings degrade over time and must be replaced after a certain number of hours determined by the manufacturer and application. The group is studying ways to increase the useable lifetime of these coatings by understanding the stresses built up in the coatings during manufacture and over time in service. A quantity known as the “stress optic coefficient,” is used to convert measured sample birefringence into stress distributions. Each material has a different coefficient, which can depend on several factors. Some things that can alter the stress optic coefficient of a material include the frequency of the radiation used in the test, the manufacturing methods, material density and atomic structure. This list is not exhaustive. Part of the research tries to understand how the stress optic coefficient of a material can change.

Dr Schemmel describes how he applies the Deben 2kN tensile stage: “In order to find the stress optic coefficient of a material, we must measure the birefringence whilst a known stress is applied to the sample. Deben’s tensile stage is indispensable to this operation. Constant loads can be applied to the sample, over the course of each birefringence measurement. Such measurements take around ten minutes. If the stress on the sample changes during this time, the measurement is invalid. Without the Deben tensile stage, we would not be able to accurately calibrate our materials.”

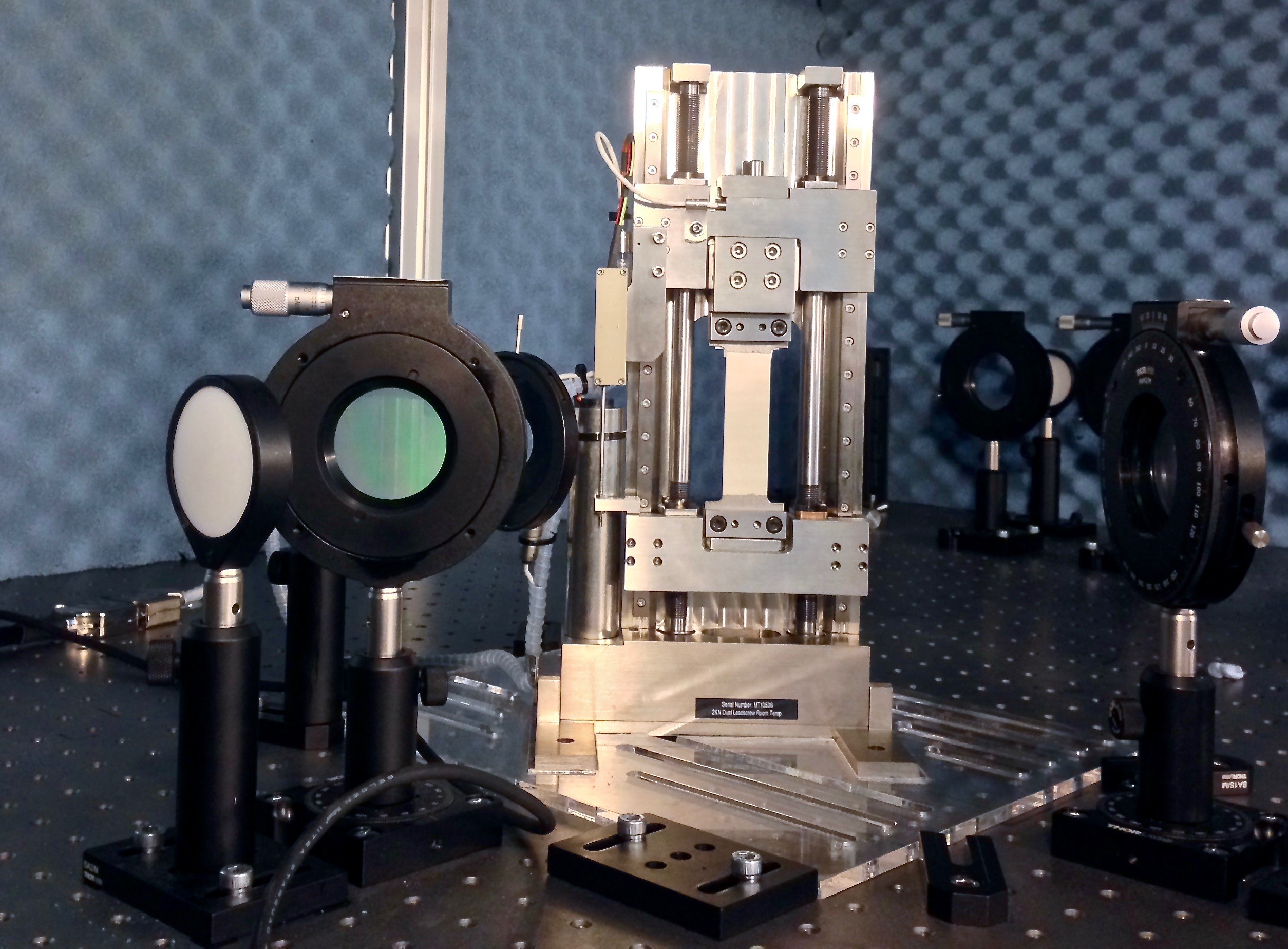

The benefits of the stage are fourfold. Dr Schemmel continues: “Firstly, it is small. We required a small stage to sit on our optical bench, inside an anechoic chamber. Secondly, Deben was able to machine a specifically sized window in the back of our tensile stage so that we could pass our GHz – THz beam through the sample under test. Thirdly, and most importantly, the Deben system allows us to control the applied load with great finesse. We are able to maintain a constant load on each sample during the birefringence measurement period, which is critical to achieve accurate results. Finally, the system is extremely easy to operate. It is really a “plug-and-play-system,” which allows us to be more productive.” Research in the group applying the stage is moving rapidly with the first publication due shortly. This will show interesting results on the stress optic coefficient of YTZP ceramic and PTFE plastic. It was found that the stress optic coefficient of some materials can depend on sample preparation variables, e.g. cutting specimens parallel or perpendicular to the extrusion direction.

You should hear from us shortly.