2kN & 5kN Tensile compression and horizontal bending stage

MICROTEST 2kN & 5kN modules have been specifically designed to allow real time observation of the high stress region of a sample with an SEM, optical microscope, AFM or XRD system. Windows 7.0/10.0 software sets drive parameters and displays the stress/strain curve live on the computer screen. Loadcells from 150N to 5kN cover most applications, with extension rates from 0.005mm/min to 50mm/min. All stages have linear scales for elongation measurement and optical encoders for speed control. Options include three and four point bending clamps, fibre clamps and microscope mounting adaptors. Modules are controlled from Microtest tensile testing software and special versions can be manufactured to customers requirements.

White papers:

Characterisation of the mechanical behaviour of sunflower stem for bio-composite applications

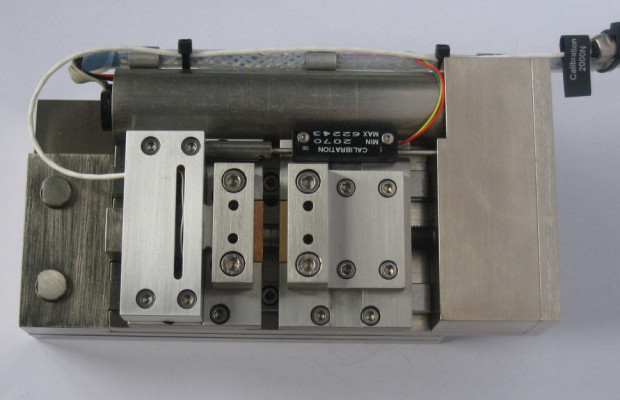

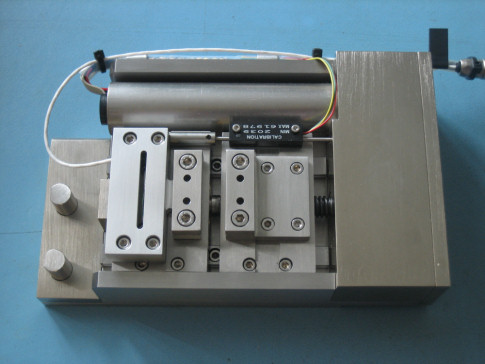

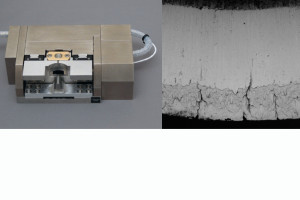

2kN tensile stage

The 2kN tensile stage uses custom minature loadcells in the range 660N to 2kN. Samples are mounted horizontally, clamped to a pair of jaws and supported on stainless steel slide bearings. A dual threaded leadscrew drives the jaws symmetrically in opposite directions, keeping the sample centred in the field of view. The 2kN module is ideally suited for use with an SEM, optical microscope or AFM and will easily fit on most stages. Applications range from polymers, thin films, fibres and thin metal samples. Custom versions are available with Peltier heating & cooling from -20°C to +160°C, extended stroke and travel.

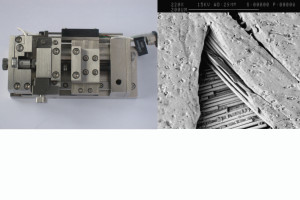

5kN tensile stage

The 5KN tensile stage is very similar to the 2KN stage except for its size and maximum force. The 5kN module can fit some larger chamber SEMs, AFMs and optical microscopes. Applications include ceramics, metals and polymers. Custom versions are available with Peltier heating & cooling from -20°C to +160°C, extended stroke and travel.

5kN tensile stage with heating & cooling

An version of the 5kN stage is available with heating and cooling jaws. Using ceramic heater cartridges the jaws can be heated to 600ºC and cooled to -150°C. The stage and loadcell are water cooled and temperature is set from an independent temperature controller with closed loop control. The system includes remote heat exchanger LN2 Dewar, and electrical feed-throughs. High or low temperature operation must be in vacuum. Alternative or additional heating/cooling methods for less thermally-conductive specimens can be considered. For non SEM applications the Deben dual leadscrew tensile stage is a better option.