Synchrotron & X-ray CT

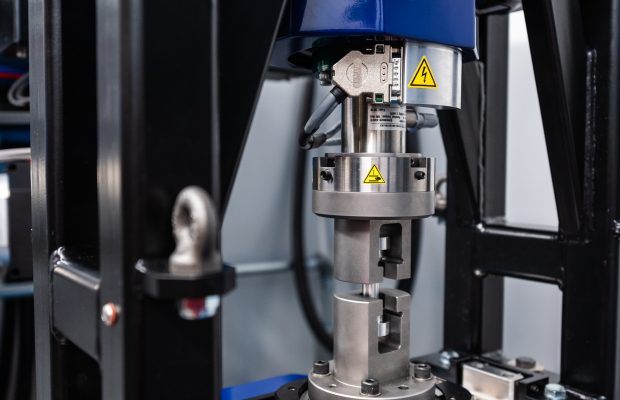

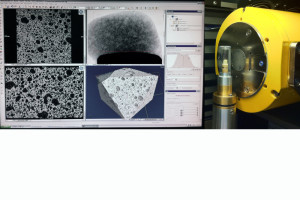

CT20K, Full Open Frame, Tensile, Compression & Torsion rig, designed for Synchrotron and room based X-ray CT imaging systems

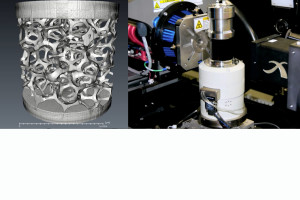

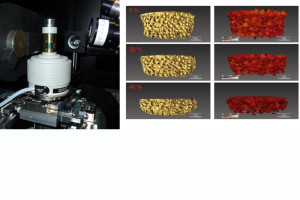

Synchrotron & X-ray Computed Tomography (XCT) Imaging — 20kN tensile, compression and torsion rig. Top and bottom jaws contain independent high resolution rotation mechanisms allowing synchronised sample rotation. Torque can be applied by rotating one jaw further than the opposite jaw up to 100Nm loading. Tensile or compression load can be applied at the same time as torsion and loads can be applied and held while the sample is being rotated.

Sample rotation can be controlled in step or continuous mode from the associated imaging system or from the supplied control software.

Many different materials may tested at loads from -20kN to +20kN, and torsion from -100Nm to +100Nm.

An optional furnace may be fitted for sample heating to 1,000ºC.

Acquisition software is supplied for system control, real-time data display and recording of force/extension curves.

Deben 20kN Open Frame X-ray Tensile/Compression & Torsion tester

We are now able to offer an integrated tensile/compression/torsion testing solution for your µXCT application. Using tensile testing with µXCT provides a clear visual interpretation of how the properties of materials and composites change under different loading conditions. The design of these testing stages allow them to be used with high resolution micro CT systems providing a range of tensile, compression and torsion stages with forces up to 20kN. Systems are controlled from the comprehensive MICROTEST tensile stage control software giving a wide range of control functions and a live display of load versus extension and supplied with all required cabling and mounting adaptors for specific µXCT systems. Further details and pricing is available from your micro CT supplier or direct from Deben.

Currently there are two versions of the CT20kN available:

- CT20kN Maximum load 20kN

CT20kN general specification:

Modular tensile & compression & torsion testing system to be installed within a µXCT system

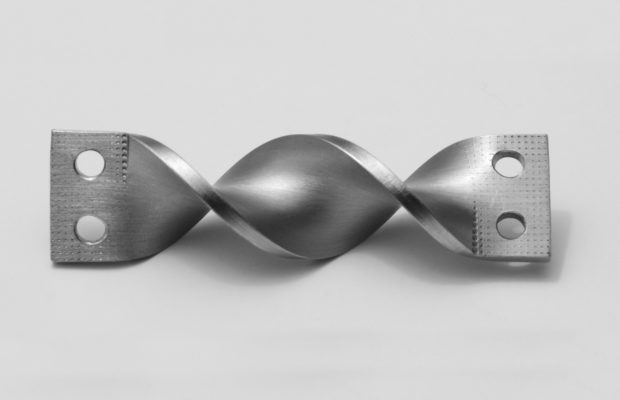

Tensile, compression and torsion jaws (can be customised to customer specifications)

Rigid design to allow very high accuracy testing in Room Based CT

- Loadcell with maximum linear load (tension and compression): +/-20kN

- Maximum torsion load: +/-100Nm

- Operating modes

- Torsion testing

- Compression testing (with or without torsion)

- Tension testing (with or without torsion)

- Rotation operating modes

- Continuous step rotation (for CT acquisition)

- Step resolution 0.001o

- 180o/s maximum; 20o/s recommended maximum

- Maximum rotations per test 1000

- Jaw movement with load & displacement control

- Linear travel between jaws 50mm; minimum step size 100nm

- Synchronised jaw rotation speed up to 15 rpm; minimum step size 0.001o

- Removable jaws to allow for different specimens/applications

- One set of standard Deben Tensile/Compression/Torsion jaws supplied for standard dumbbell sample.

- Custom mounting adaptor included

- Installation

- Stage controller and operation s/w included, 6U rack mounting kit included

- One set of 10m cables supplied

- Power requirements: 230V 50Hz 2400VA single phase

- Approx weight 120kg; Lifting eyes on the frame to suit M10 eye bolts.

- No manual handling equipment included but will be required.

Other Deben in-situ stage systems available for µXCT applications:

- CT5000 5kN in-situ tensile stage with heating & cooling options

- CT350 heating stage with temperature range room temperature to +350°C

- CT500 500N in-situ tensile stage

- CT160 Peltier stage with temperature range -20°C to +160°C